Codabix Industrial Data Hub

OPC UA Middleware and Smart Factory Maker

How to use

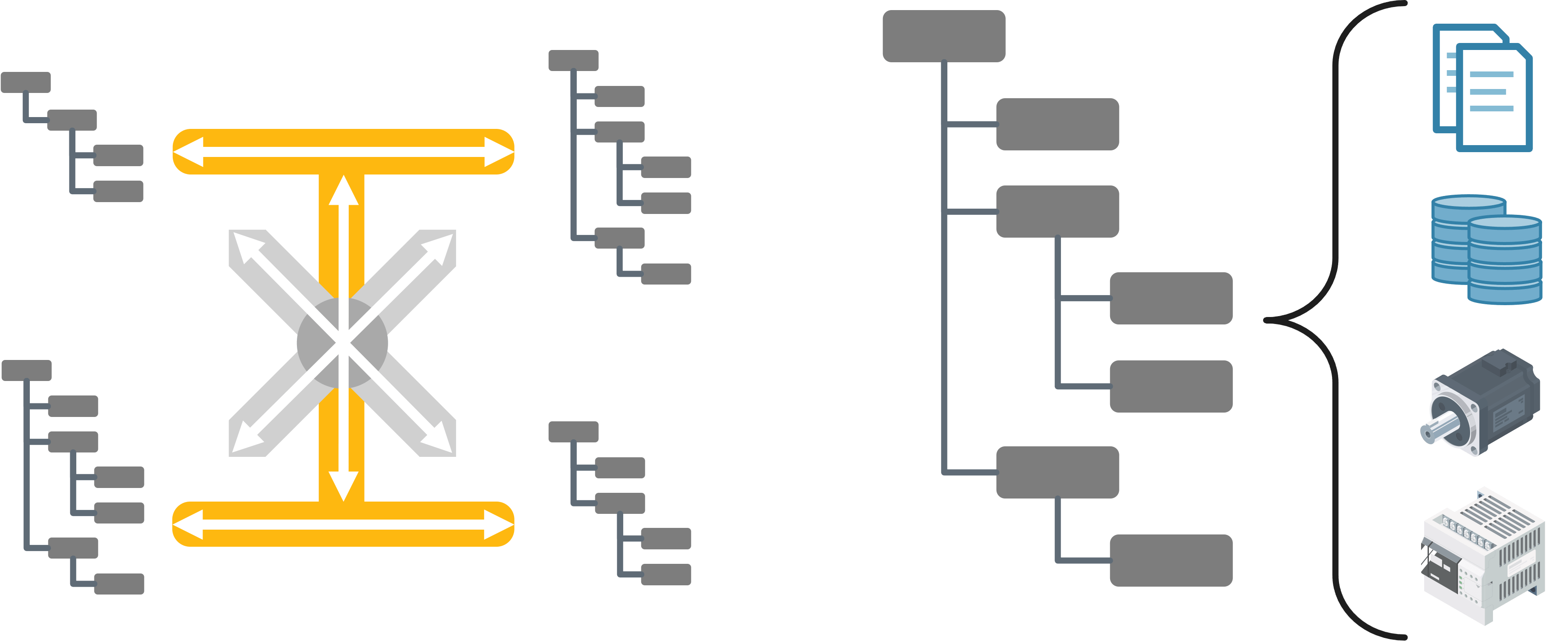

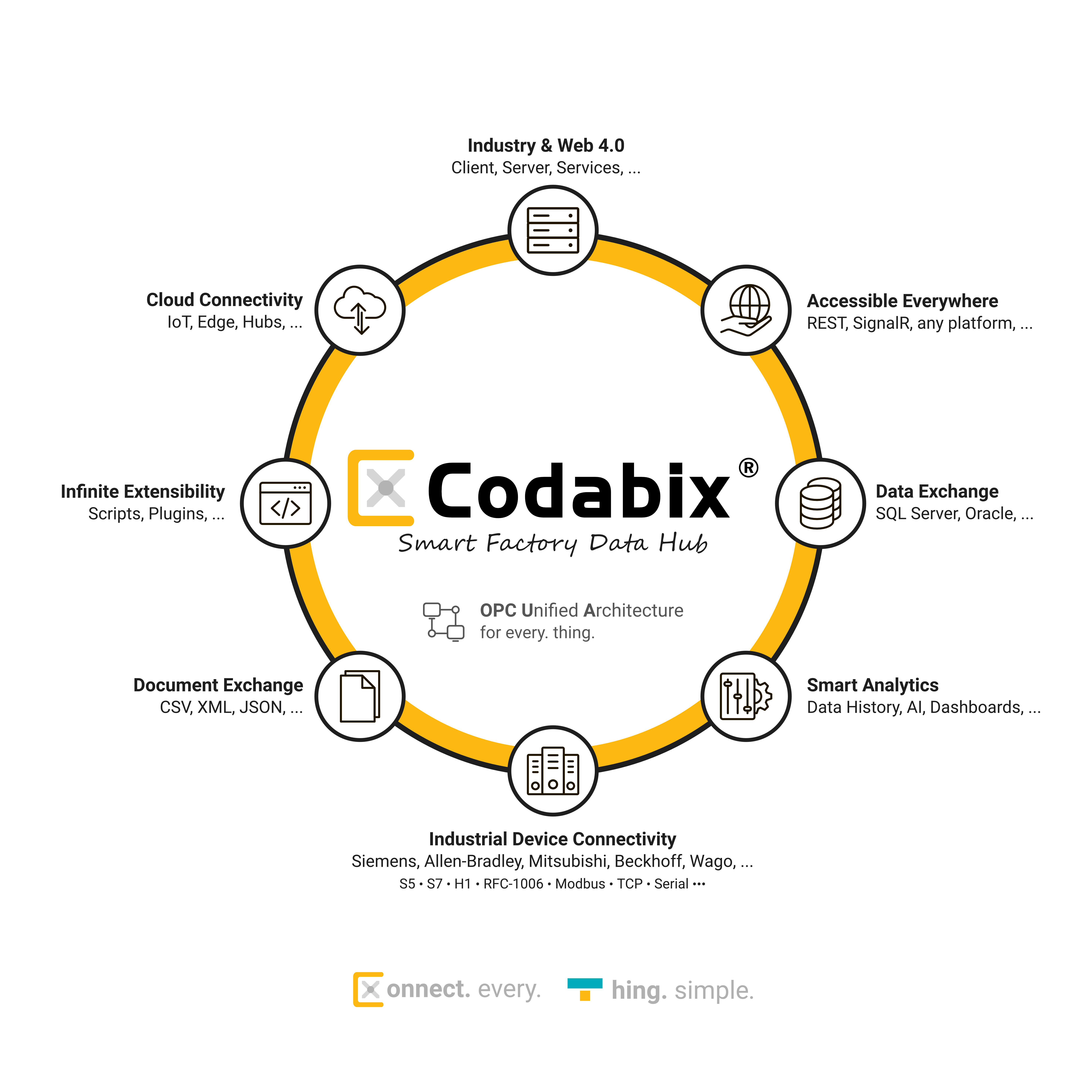

With the hub version of the Industry 4.0 middleware your industrial (r)evolution will succeed! While individual participants are bundled directly as IoT and entire islands of manufacturing via edge computing, the data hub brings them together as a superordinate instance. As a junction between the top floor and the shop floor, the hub realises the long-awaited vertical integration. Regardless of whether it then cooperates directly with the device manager, provides master dashboards, acts as a further gateway, smart data router for further participants or as an interface to the distributed control system (DCS): This is the data highway of your Smart Factory!

As with Industrial IoT or Industrial Edge, the Data Hub also unites heterogeneous participants along the entire process chain, standardises their data points at the same time in accordance with OPC UA (IEC 62541) and breathes the necessary life into them with its own business logic for the coordinated data flow. Completely abstracted from the underlying type of communication, active as well as passive protagonists are connected with each other.

At the level of Industry 4.0, every datum is exchanged bidirectionally (in both directions) between data source and data destination (also vice versa) without the use of a specific language. Whether via a simple handshake, a data subscription or via PubSub: the data is always consistently available and can be transparently processed further.

Platform-independent, the hub can grow with the size of the Smart Factory, from the small Raspberry Pi to the first physical cluster up to your own Kubernetes infrastructure: The middleware feels at home everywhere.

The best:

- No change of hardware and software configuration!

- No licences from Siemens and Co. necessary!

- No follow-up costs and no SaaS commitment!

- No restriction of know-how!

- No change of processes!

Top / Shop Floor Upgrade

Real digitalisation knows no compromises and no limits – just like Codabix! With the Communication Data Bridge for Things (x), no participant is forgotten and every datum is recorded down to the last bit – whether mechanically, electrically or logically generated. The retrofit portfolio of the middleware does not simply exclude actuators and sensors via sockets, scanners and scales via serial ports, dusty controllers and plants via ISO 8073 Class 0 communication or ISO-H1, and ODBC data sources such as Microsoft Access databases.

Communication protocols and techniques that have long been abandoned by their creators are experiencing a revival in the middleware! Regardless of the provider and manufacturer, controllers, for example, are easily connected via the predecessor of OPC UA using OPC Classic (consisting of OPC DA, OPC HDA and OPC AE) and equipped with OPC UA.

The necessary translators and drivers are already included in the Hub ex works!

If there is not yet an interface for the type of "museum piece", then this is simply created. Either on our own, in cooperation or as an integration service by our developers – that's how Industry 4.0 works.

Simply get in touch with us!

Data Hub 4.0

The use of the middleware as a data hub unites not only top and shop floor, but also the (already) developed fields of Industrial IoT and Industrial Edge. Due to the multitude of connectivity options, scenarios for "load balancing" of production, historical data collection for the collection of OEE factors and the monitoring of individual plants to predict the next maintenance (= Predictive Maintenance, PM for short) find the best conditions here – not least also for the visualisation of data or even interaction via augmented reality (AR) with the participants.

Due to the predestined positioning of the data hub as the interface between the top floor and the shop floor, it represents the backbone of your smart factory. Because while all results, states and signals (which require a decision) typically do not escape the hub, it can be equipped with the necessary intelligence for Automation 4.0. Whether as smart business logic cast in script code based on years of experience or freshly trained AI (at the Digital Twin) – the middleware provides the necessary access to the participants.

(R-)Evolution of Digitalisation

Many talk about the "industry with data lake", but nobody needs data octopuses in it! Because the more seemingly delicious live process images are served, the more cumbersome and hungry the small and weak participants become – until they starve. Bandwidth and computing time are not available in unlimited amounts, which is why these also represent the limits of the Industry 4.0 solution spaces.

Against the background of the increasingly necessary database for modelling and training artificially intelligent actuators, the Data Hub offers a robust solution. While time-critical processes are carried out directly in the Industrial IoT or at the Industrial Edge, the hub can bring together all the necessary data from these, process it and make it available for training the AI.

The reduced influence on the performance of the participants thus leads to a realistically trained AI, which can also control and regulate the intelligent data flow control directly at the hub via the participants at the Industrial IoT or at the Industrial Edge. The optimisations of the accesses via the middleware already known from the fieldbus level thus lead to the decisive lever that finalises the processes of your Smart Factory and thus nothing more stands in the way of Industry 4.0.

Advantages

- Free evaluation without registration

- Easy and fast digitisation

- Industrial reliability

- Qualified support

- Comprehensive documentation

- Regular updates

Characteristics

- Comprehensive OPC UA features

- Guaranteed connectivity

- Headless operation

- Historical data

- Maximum speed

- Interface Modelling

- Plugin System

- Role-based access control

- Configuration import/export

- Node-based data model

- Platform independent

Functional Scope

Codabix in the Industrial Data Hub version connects the interface between the top floor and the shop floor, acting as an Industry 4.0 gateway and smart data router. The extensive number of supported connectivity solutions enables the use as a data hub including crucial (artificial) logic. The connection of up to 50 identical and different components, devices and systems via open and proprietary protocols is supported. These can also be coupled with up to 50 further passive participants of various database and file systems.

For the finalisation of digitalisation and the realisation of Industry 4.0, the Data Hub provides an integrated scripting environment for its own know-how for the control and regulation of processes according to years of experience. The connection of processes and modules of a trained AI can be realised directly via the integrated OPC UA server with up to 50 OPC UA clients simultaneously. For visualisation, whether classically offline or online, partially virtual (AR) or completely virtual (VR), the data structures can be structured accordingly and prepared for graphical representation. To retrieve this data, an unlimited number of additional clients can be used via HTTP(S) via REST API, REST JSON API and SignalR API.

Even more options? The customised version: Codabix Enterprise

Clustering

If a multiple of the supported number of participants is required, additional "cluster" licences can be purchased to upgrade the standard licence. The range of functions is multiplied according to the number of "cluster" licences. In this way, the step-by-step expansion of the gateway/router is possible without further installations/instances.

Services

Each purchased licence includes Traeger's top level support by our developers, as well as updates including new functions – during the purchased support period. Requests are prioritised and follow-up offers for the expansion of the middleware, any integration services or the training of developers and users including certification can be taken up.

Licensing

Unlimited Licence

Once purchased, a licence is valid indefinitely (= unlimited licence lifetime) and allows use without further licence costs (= royalty-free). Shortly before the support expires, it is possible to extend it for at least another 12 months for 15% of the current list price. Updates and new functions can only be obtained with valid support. Support requests can still be submitted, but will be processed on a priority basis depending on their scope. Up to one month before the expiry of active support, we will notify you of the possibility of support renewal. After expiry, a new licence must be purchased for the support renewal. This type of licence can not be used in container environments (such as Docker).

Subscription Licence

Once purchased, a licence is valid for an unlimited period (= unlimited annual licence) and allows use without further licence costs for one year (= annually royalty-free). Shortly before the expiry of the annual subscription (up to one month before), we will notify you about the possibility of extending the subscription. The renewal includes a further 12 months of top level support from our developers as well as updates including new functions. Only with a valid subscription can the application continue to be used and updates and new functions be obtained. Support requests can still be submitted, but will be processed on a priority basis depending on the scope. This type of licence can also be used in container environments (such as Docker).

Features

- Devices via the mentioned ...

Protocols, interfaces and own ways

- Devices and controllers from ...

Allen-Bradley / Rockwell, Beckhoff, Bosch, Mitsubishi, Omron, Siemens, Wago and more

- Systems and machines from ...

Arburg, Engel, Krauss-Maffei, Sumitomo Demag and more

- Components via the interfaces of ...

DELL Edge Gateway, Raspberry Pi, Siemens IOT2050, UniPi, RevolutionPi and more

- Systems and subsystems via ...

CSV, XML, JSON, Excel, Access and more

- Database systems via ...

SQL, SQLite, MySql, MariaDB, PostgreSQL, Microsoft SQL Server, Oracle, Microsoft Access and more

- Integrated scripting environment

own business logic can be implemented online using TypeScript

- Supported protocols

Allen-Bradley or Rockwell EtherNet/IP, Beckhoff ADS, Mitsubishi Melsec, Omron FINS, Omron Host-Link / C-Mode Commands and more

- Supported Siemens protocols

SIMATIC H1, SIMATIC S7, SINUMERIK PL/SL and more

- Supported RAW protocols

I2C, RAW Serial Port, RAW TCP Socket and more

- Supported Standard Protocols

RFC-1006, Modbus TCP, Modbus RTU, MQTT Publisher/Subscriber, OPC UA, OPC Classic (OPC DA, OPC HDA and OPC AE), EUROMAP 63 and more

- Supported interfaces

OPC UA Server, REST API, REST JSON API, SignalR API, HTTP(S) Web Server, Plugins and Scripts

- Supported platforms

Windows, Linux, macOS and Docker

- Other features

Simple HMI and custom dashboard design