Codabix Industrial Edge

Smart OPC UA Gateway and Router for any edge scenario

How to use

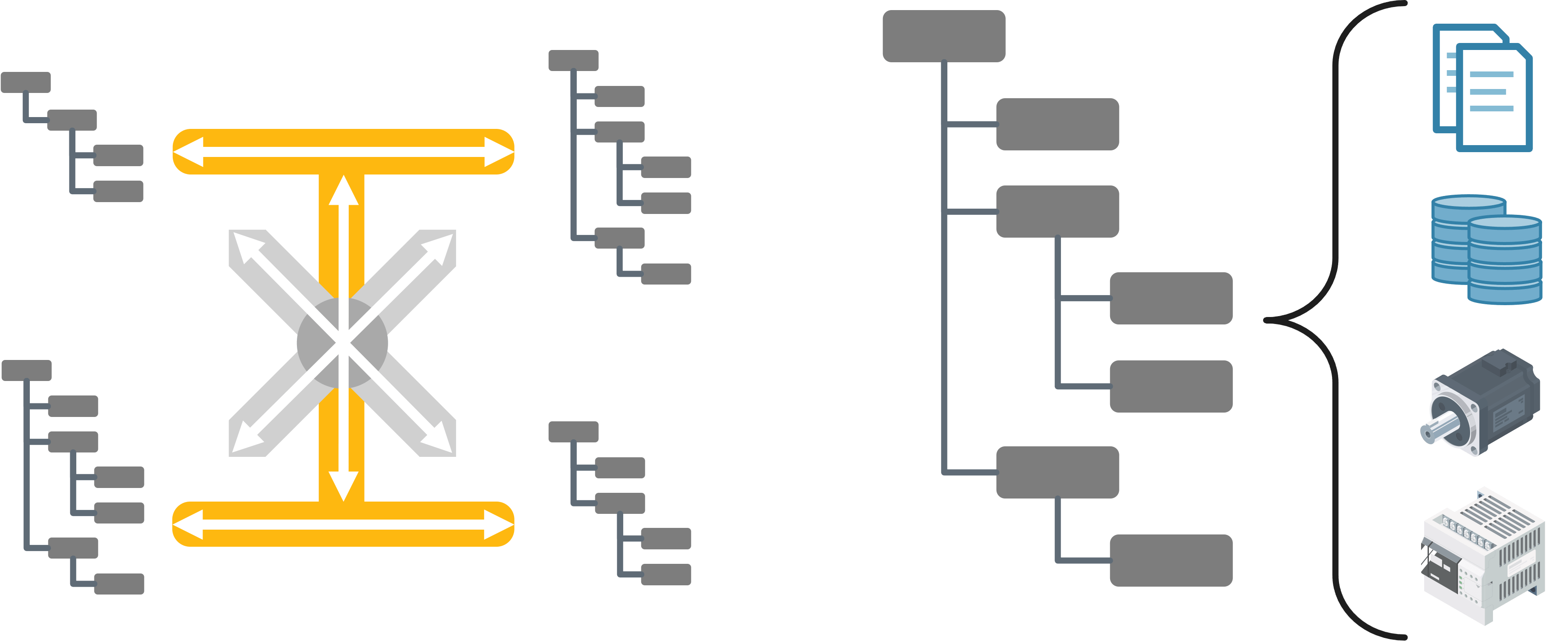

At the edge, the pulse of the data between manufacturing and planning can be felt. With the medium version of the Industry 4.0 middleware, the edge device becomes the vein of the edge field! Because heterogeneous participants from the top floor and the shop floor cross the boundaries of the IT and OT levels and become part of the horizontal and vertical integration – without losing the security they have gained.

While databases, files and other media of the top floor and controllers up to entire systems of the shop floor are networked at the edge, their data points are standardised at the same time according to OPC UA (IEC 62541). Each type of data flow in the edge field can be specifically controlled, regulated and triggered via its own business logic. Every access to the participants is completely abstracted.

Without knowledge of database dialects, transport protocols or file formats, complete communication is thus possible horizontally and vertically. This type of integration can be configured either locally or remotely in the browser. Platform-independent, any edge device can be selected and the middleware can be networked and operated directly on the device or as a container in Docker and the like.

The best:

- No change of hardware and software configuration!

- No licences from Siemens and Co. necessary!

- No follow-up costs and no SaaS commitment!

- No restriction of know-how!

- No change of processes!

Brownfield meets Greenfield

The existing possibilities for connectivity of "old" and "new" participants, regardless of whether they are on the top floor or the shop floor, are supported across all manufacturers. Be it the yellow SIMATIC S5, the pale blue SIMATIC S7 controllers or grey PLCs from Allen-Bradley / Rockwell, AEG, Beckhoff, Bosch, Mitsubishi, Omron, Wago and Co, they all automatically receive their Industry 4.0 upgrade through the middleware.

Forgotten protocols such as ISO-H1, RFC 1006 (ISO-on-TCP), serial and RAW socket protocols are just as well addressed by the middleware as their modern successors. While the data points of the participants are available via the Industry 4.0 protocol OPC UA, the old (D)COM servers can also be connected via OPC Classic (consisting of OPC DA, OPC HDA and OPC AE).

The necessary translators are already included in the gateway ex works!

The data basis from the top floor, which is important for production, is also obtained from (antique) Microsoft Access databases, ODBC data sources or simple and structured files. While views, tables and their columns are standard, depending on the provider, stored procedures and functions can be addressed via OPC UA just like their active participants from the shop floor.

The provider-specific drivers are included ex works!

Data Pulse 4.0

Every connected data source automatically also becomes a data sink, which means that data can no longer flow only unidirectionally (in one direction), but also bidirectionally (in both directions) and thus from the source to the destination and vice versa. The view of the data is also completely free to model and, in connection with the historical record, can also be visualised in the browser over long periods of time.

Decisive processes for actions and reactions can be triggered by means of handshakes, time-/event-controlled triggers, by clicking by the user and by the participants themselves. The Scripting, which is independent of the limitations of a visual programming environment, can be realised directly online in the browser as well as during operation. From where to where and, above all, when and how the data flows – that is up to you, independent of the manufacturer and provider of the data points.

(R-)Evolution of Digitalisation

The intelligent data collection and data processing is the task of the edge device. Blunt dumping of all participants is rarely smart enough to meet the requirements of Industry 4.0. While the middleware also supports classic dumping, intelligent and event-driven processes can be realised instead. In the process, the connected (old) components, controllers and systems are not thrown out of sync and the bandwidth of the line to them is also spared.

If the data is then accessed from databases, files, components and controllers, access is further optimised and the communication effort is reduced to a minimum. Peculiarities of the participants due to the (forced) use of older firmware or specific communication patterns are not a problem. **Each participant connected to the Edge becomes directly part of new process chains.

Advantages

- Free evaluation without registration

- Easy and fast digitisation

- Industrial reliability

- Qualified support

- Comprehensive documentation

- Regular updates

Characteristics

- Comprehensive OPC UA features

- Guaranteed connectivity

- Headless operation

- Historical data

- Maximum speed

- Interface Modelling

- Plugin System

- Role-based access control

- Configuration import/export

- Node-based data model

- Platform independent

Functional Scope

The Industrial Edge version of Codabix acts as an Industry 4.0 gateway and smart data router that combines the possibilities of the Industrial IoT with those of a smart edge solution. It supports the connection of up to five identical and different components, devices and systems via open and proprietary protocols. A further five heterogeneous data sources/sinks in the form of databases and files also find the necessary connectivity here. In order to be able to implement one's own know-how according to individual requirements, the middleware also provides an integrated scripting environment for one's own business processes.

Once defined, each data point, regardless of whether from a participant or from your own business logic, can be consumed directly via the integrated OPC UA Server with up to five OPC UA Clients simultaneously. Thanks to smart data processing, the data structures, which can be freely modelled at the same time, can then also be used interactively with an unlimited number of additional clients via HTTP(S) using REST API, REST JSON API and SignalR API in unlimited further Industry 4.0 edge scenarios.

Not enough yet? The Industrial Data Hub version can do even more!

Clustering

If a multiple of the supported number of participants is required, additional "cluster" licences can be purchased to upgrade the standard licence. The range of functions is multiplied according to the number of "cluster" licences. In this way, the step-by-step expansion of the gateway/router is possible without further installations/instances.

Services

Each purchased licence includes Traeger's top level support by our developers, as well as updates including new functions – during the purchased support period. Requests are prioritised and follow-up offers for the expansion of the middleware, any integration services or the training of developers and users including certification can be taken up.

Licensing

Unlimited Licence

Once purchased, a licence is valid indefinitely (= unlimited licence lifetime) and allows use without further licence costs (= royalty-free). Shortly before the support expires, it is possible to extend it for at least another 12 months for 15% of the current list price. Updates and new functions can only be obtained with valid support. Support requests can still be submitted, but will be processed on a priority basis depending on their scope. Up to one month before the expiry of active support, we will notify you of the possibility of support renewal. After expiry, a new licence must be purchased for the support renewal. This type of licence can not be used in container environments (such as Docker).

Subscription Licence

Once purchased, a licence is valid for an unlimited period (= unlimited annual licence) and allows use without further licence costs for one year (= annually royalty-free). Shortly before the expiry of the annual subscription (up to one month before), we will notify you about the possibility of extending the subscription. The renewal includes a further 12 months of top level support from our developers as well as updates including new functions. Only with a valid subscription can the application continue to be used and updates and new functions be obtained. Support requests can still be submitted, but will be processed on a priority basis depending on the scope. This type of licence can also be used in container environments (such as Docker).

Features

- Devices via the mentioned ...

Protocols, interfaces and own ways

- Devices and controllers from ...

Allen-Bradley / Rockwell, Beckhoff, Bosch, Mitsubishi, Omron, Siemens, Wago and more

- Systems and machines from ...

Arburg, Engel, Krauss-Maffei, Sumitomo Demag and more

- Components via the interfaces of ...

DELL Edge Gateway, Raspberry Pi, Siemens IOT2050, UniPi, RevolutionPi and more

- Systems and subsystems via ...

CSV, XML, JSON, Excel, Access and more

- Database systems via ...

SQL, SQLite, MySql, MariaDB, PostgreSQL, Microsoft SQL Server, Oracle, Microsoft Access and more

- Integrated scripting environment

own business logic can be implemented online using TypeScript

- Supported protocols

Allen-Bradley or Rockwell EtherNet/IP, Beckhoff ADS, Mitsubishi Melsec, Omron FINS, Omron Host-Link / C-Mode Commands and more

- Supported Siemens protocols

SIMATIC H1, SIMATIC S7, SINUMERIK PL/SL and more

- Supported RAW protocols

I2C, RAW Serial Port, RAW TCP Socket and more

- Supported Standard Protocols

RFC-1006, Modbus TCP, Modbus RTU, MQTT Publisher/Subscriber, OPC UA, OPC Classic (OPC DA, OPC HDA and OPC AE), EUROMAP 63 and more

- Supported interfaces

OPC UA Server, REST API, REST JSON API, SignalR API, HTTP(S) Web Server, Plugins and Scripts

- Supported platforms

Windows, Linux, macOS and Docker

- Other features

Simple HMI and custom dashboard design